Our Philosophy

DERMAFIRM was established in 2002 based on our motto – “The most important thing

is invisible to the eye.” At the time, cosmetic companies lacked transparency about the

concept and production process of the importance of good raw materials. Therefore, we established a cosmetic brand that uses produces its own raw materials that are proven to be effective through extensive research. Since our establishment, DERMAFIRM has been operating to produce high-purity and functional raw ingredients in our very own production facilities so we can make trusted derma cosmetics accessible to all.

Sincerity with premium ingredients & innovation

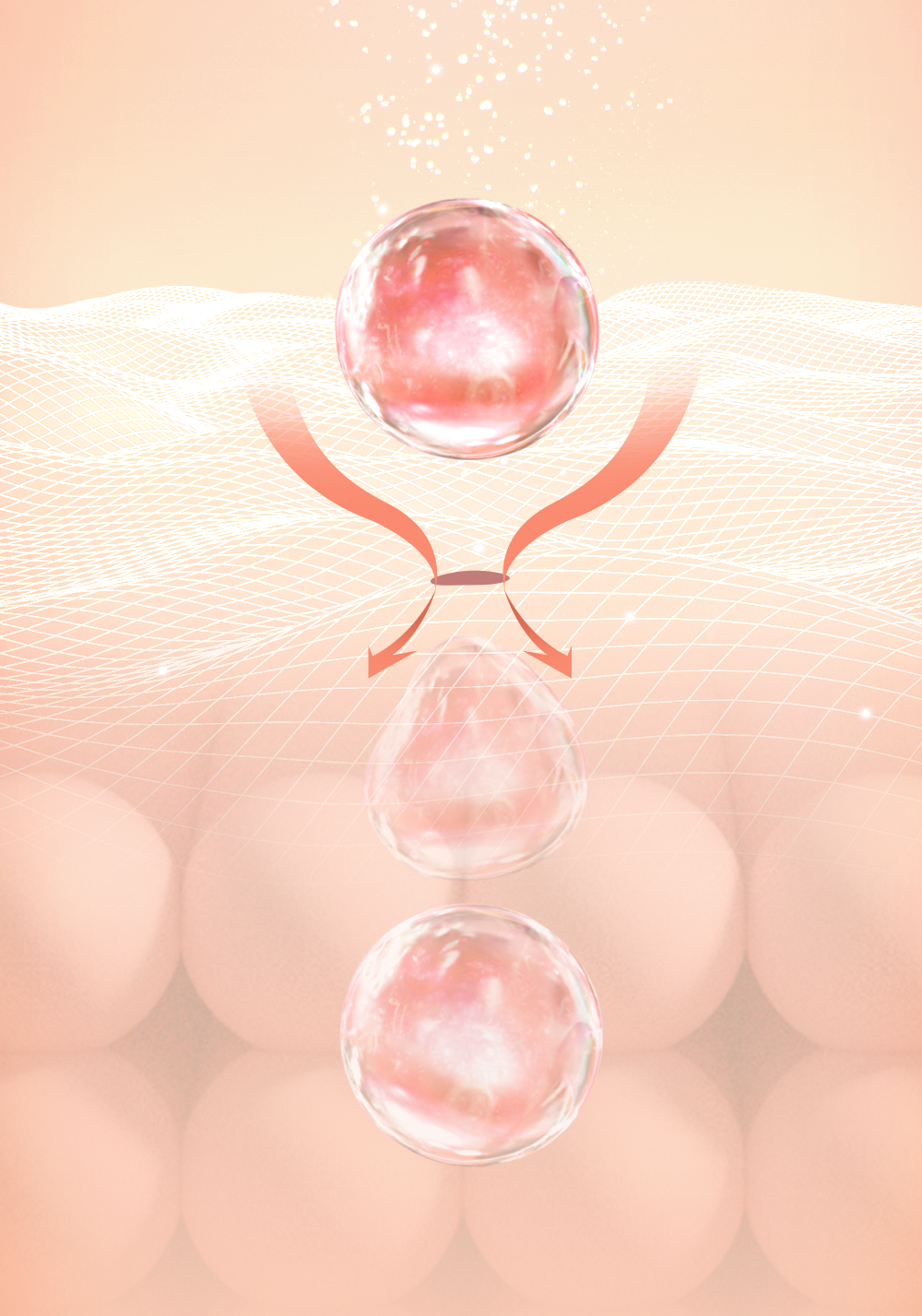

Our groundbreaking formula utilizes Liposomes—a transdermal drug delivery system

(TDDS)—to deliver active ingredients to the skin quickly and efficiently. We’ve improved

the stability of our ingredients by encapsulating active components between double

layers of phospholipids, allowing our products to deliver powerful agents securely to the

skin. DERMAFIRM’s revolutionary Liposomes enable carefully chosen ingredients such

as Peptides, Azulene, and Astaxanthin, to penetrate the dermis effectively, achieving

clinically-proven, visible results.

We utilize a collection of 22 functional peptides known to assist with anti-aging, skin brightening, and hair strengthening. Our innovative patented peptides— Heptapeptide-48 and Palmitoyl heptapeptide-48—were developed by DERMAFIRM’s scientific experts in-house for our powerful anti-aging formulations.

DERMAFIRM has undertaken new scientific research to understand how microbiomes can impact skin disorders, developing a patented microbiome technology called Terrabiome® made with fermentation and natural extracts. This transformative property assists with balancing the ecosystem for healthier, better-functioning skin.

Belief in Science

In order to stay true to the essence of Derma Cosmetics, DERMAFIRM does not

depend on external OEM/ODM cosmetic manufacturers. Instead, we make efforts to

strengthen our own R&D capabilities. Our four research institutes include the Derma

Science Research Center, the Peptide Research Center, the Medical Device Research

Center, and the Natural Materials Research Center, in which 30% of our workforce is

employed. As a result, we have the best R&D capabilities in the domestic derma

cosmetics industry. Through this, we have been able to research skin microbiome

design and new production technology, as well as produce new material peptides and

liposome technology.

DERMAFIRM’s Global Presence

DERMAFIRM began developing cosmetics exclusively for hospitals and clinics in 2005,

and is now widely recognized for our excellence in more than 30 countries worldwide.

We actively communicate with our customers to guarantee superior sales and quality assurance services.

As a pioneer in the skincare industry, DERMAFIRM is leading the way for K-beauty

globally through the use of trusted dermatological science and creative innovation.

Open Innovation

Open innovation at DERMAFIRM is built on ongoing scientific study and partnership with top laboratories around the globe. We continually work to create new materials using the newest delivery method.

-

DERMAFIRM collaborates with Abio Materials which has patent 3rd generation exosome extraction technology (ExotractionTM). Exosomes are lipid bilayer enclosed nano-sized extracellular micro-vesicles secreted by all living cells. The exosome is a promising smart delivery system as well as new material itself for pharmaceutics and cosmetics.

-

DERMAFIRM collaborates with SCAI Therapeutics to improve penetration like HA, PDRN, Azulene, etc. MOASIS (MOlecular ASsociated Innovative Substance) is SCAI Therapeutics’ patented delivery technology. MOASIS technology improves the permeability, solubility, and stability of specific substances.

The DERMAFIRM Wonju Plant

The main DERMAFIRM plant is housed in a cutting-edge smart factory, measuring 40,000 sq. feet in size and four stories high, equipped with a “Full Cell Line” for cosmetic products, which enables one-stop production from raw materials formulation to filling and packaging all in one place with a capacity of over 2,500 tons a year as well as high-quality medical device production facilities.

The factory also has the capacity for more than 400 tons of products and features an advanced distribution system, allowing products to be quickly distributed all over the globe. It is ISO (CGMP) certified, guaranteeing that products are made in a regulatory-approved facility and ensuring the quality control steps to produce safe and effective products.